Welcome to Linear Plastics

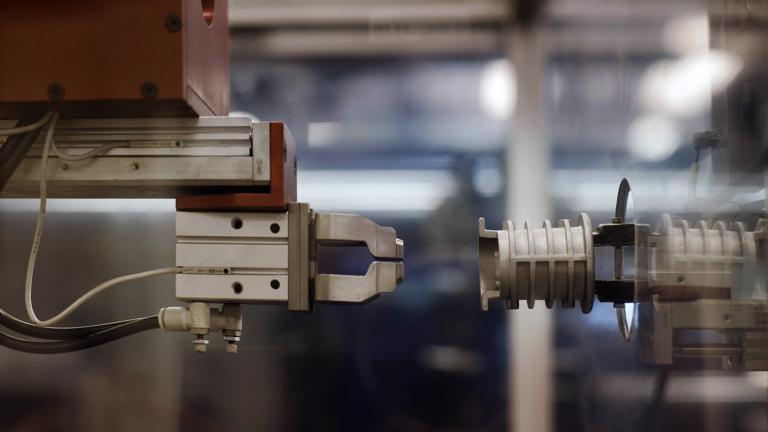

As a preferred supplier to various industrial markets, Linear Plastics is a leading UK injection moulder and toolmaker.

We provide our customers with full technical support right through from product design stage, prototyping, tooling development, series tooling, manufacturing, assembly and finally dispatch of finished product, including in some cases as “ship to line”.

Our supply-side is capable of rapid tooling with lead-times of 2 to 3 weeks, whilst also offering series products to customers in batch sizes ranging from single figures up to millions. We specialise in the over-moulding of metal inserts and also the assembly of plastic and metal components. We look forward to doing business with you.

Services

Testimonials

Daniel Williams Wittmann Battenfeld UKWe are delighted to see Linear Plastics reaping the rewards of its hard work — and further investing in the SmartPower capability.

Ewan Tozer OrangeboxWe have worked with Linear Plastics for nearly 30 years and they have grown to become a strategic supplier. They get involved from concept design all the way through to mass production and provide a consistently high level of service.

Tony Morgan One-Nine-DesignDuring 2019 we placed a considerable portion of our business with LP and the results have proven very successful. We were looking for a local manufacturing partner that offered scalability and professionalism, but still with a personal touch — we found just that.